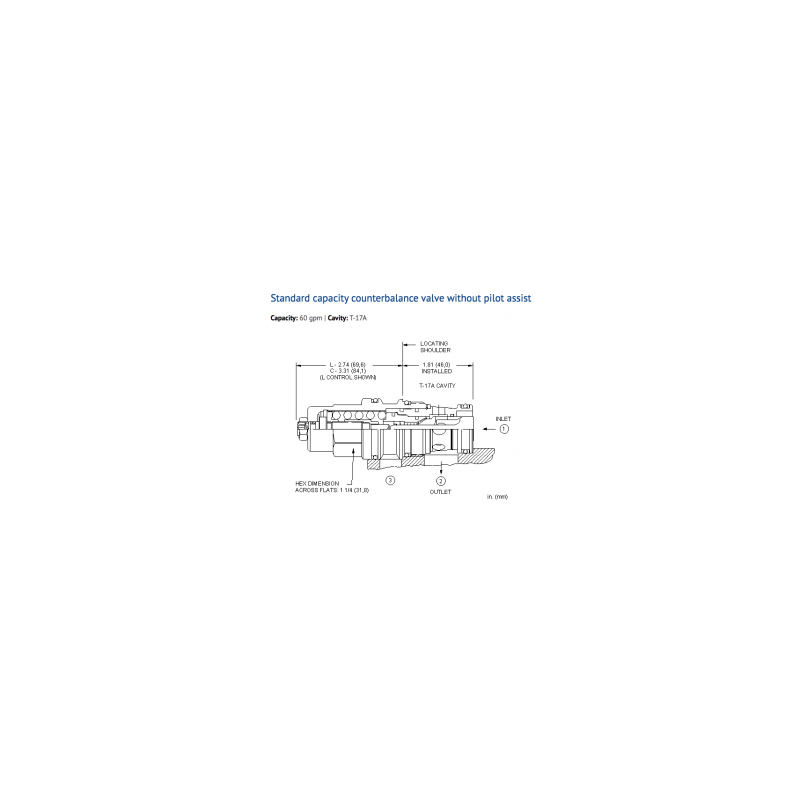

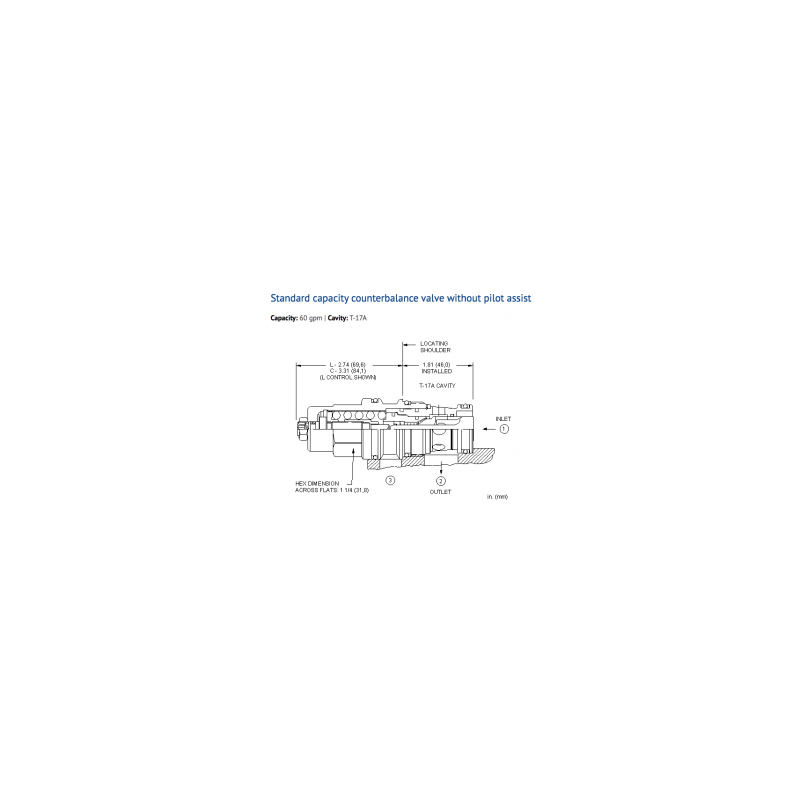

Counterbalance valves without pilot assist are meant to control an overrunning load. The check valve allows free flow from the directional valve (port 2) to the load (port 1) while a direct-acting relief valve controls flow from port 1 to port 2. Counterbalance valves should be set at least 1.3 times the maximum load induced pressure. Turn adjustment clockwise to decrease setting and release load. Full clockwise setting is less than 200 psi (14 bar). These valves are modified versions of our pilot assisted counterbalance valves. The pilot assist area has been nullified internally. There is no connection to port 3. Backpressure at port 2 is directly additive to the relief setting of the valve. Lower pilot ratios (pilot gain) promote machine stability. This valve has a pilot ratio of zero. Stability is gained at the expense of efficiency. Reseat exceeds 85% of set pressure when the valve is standard set. Settings lower than the standard set pressure may result in lower reseat percentages. All 3-port counterbalance, load control, and pilot-to-open check cartridges are physically interchangeable (i.e. same flow path, same cavity for a given frame size). Sun counterbalance cartridges can be installed directly into a cavity machined in an actuator housing for added protection and improved stiffness in the circuit. Two check valve cracking pressures are available. Use the 25 psi (1,7 bar) check unless actuator cavitation is a concern.